Important Characteristics of Using Linear Guide Rails

A linear rail guide is one kind of system that helps with right movement & supporting of a load of equipment in the linear way, it can be horizontally or vertically. Miniature versions of the linearführungsschiene system are stocked in the hardened stainless steel.

Characteristics of the linear rail

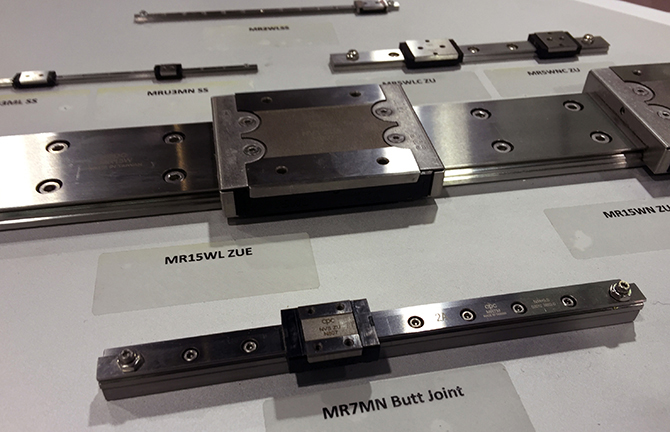

Linear guidance system includes 2 important parts: rail and runner. Runner part moves in the rail, forward to backward. The roller bearings are its moving parts of an assembly and are well-equipped with the threads that will fix any object to get moved rightly.

Bearing

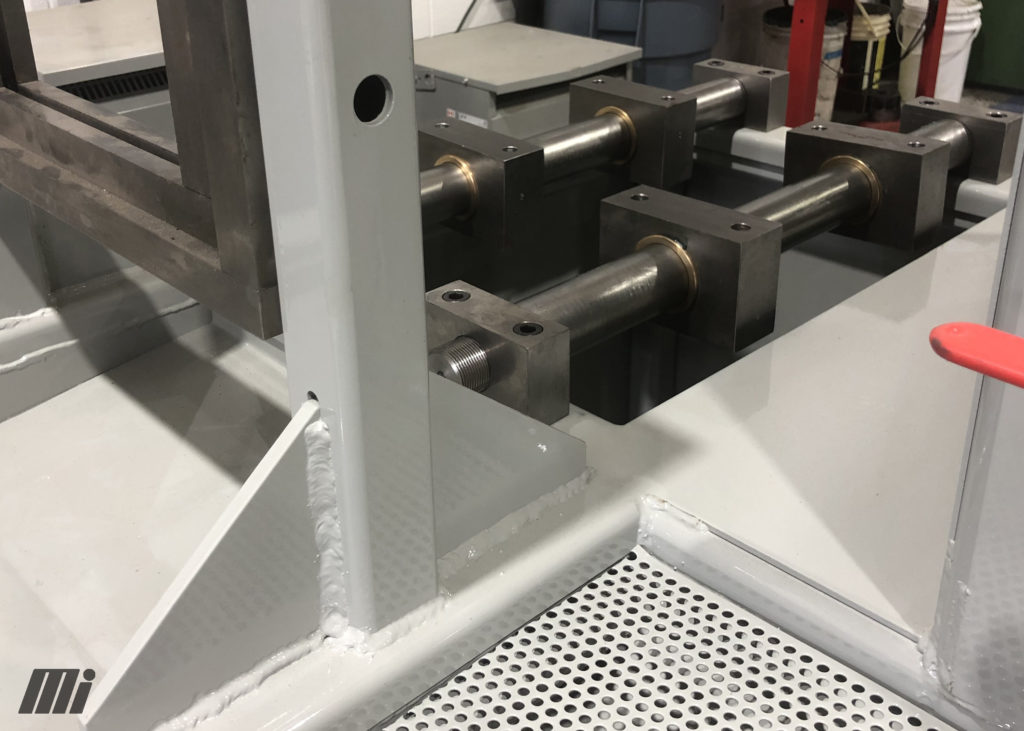

The linear guide rails are made of high-strength galvanized steel that will offer the right corrosion-resistant product. They’re made by the cold drawing procedure that shapes & profiles metal to give proper shape of a rail before getting equipped with the roller runner.

Dimensions

The devices come in different sizes and shapes. But, some forms are highly common in an industrial sector. The profiled linear rail guides are appropriate for the high loads and are made to create an exact linear motion just by having the rectangular shape thick for the linear bearing to get firmly fixed.

Common Linear Rail Applications

Because there are a huge variety of accuracy classes, sizes, as well as preloads available, the Linear Rails are appropriate in any circumstance. The linear rails generally tend to perform much better than various other devices due to its load capacity, rigidity and displacement accuracy. For such reason the Linear Rails form basis of several varied industrial usage.

When you want the low-friction system with the high rigidity for weighing some grams to tons, there is the linear rail appropriate for the unique performance needs. The load capacity, accuracy, as well as rigidity are much better than any other solutions out there.